Engineered for Simplicity

Our approach emphasizes right-fit technology tailored to your production — whether that is a full-scale new build, a custom integration, or a unique upgrade. That means prioritizing operator-friendly controls that enhance usability, and advanced data analytics that provide valuable insights into performance and productivity.

Designed for Longevity

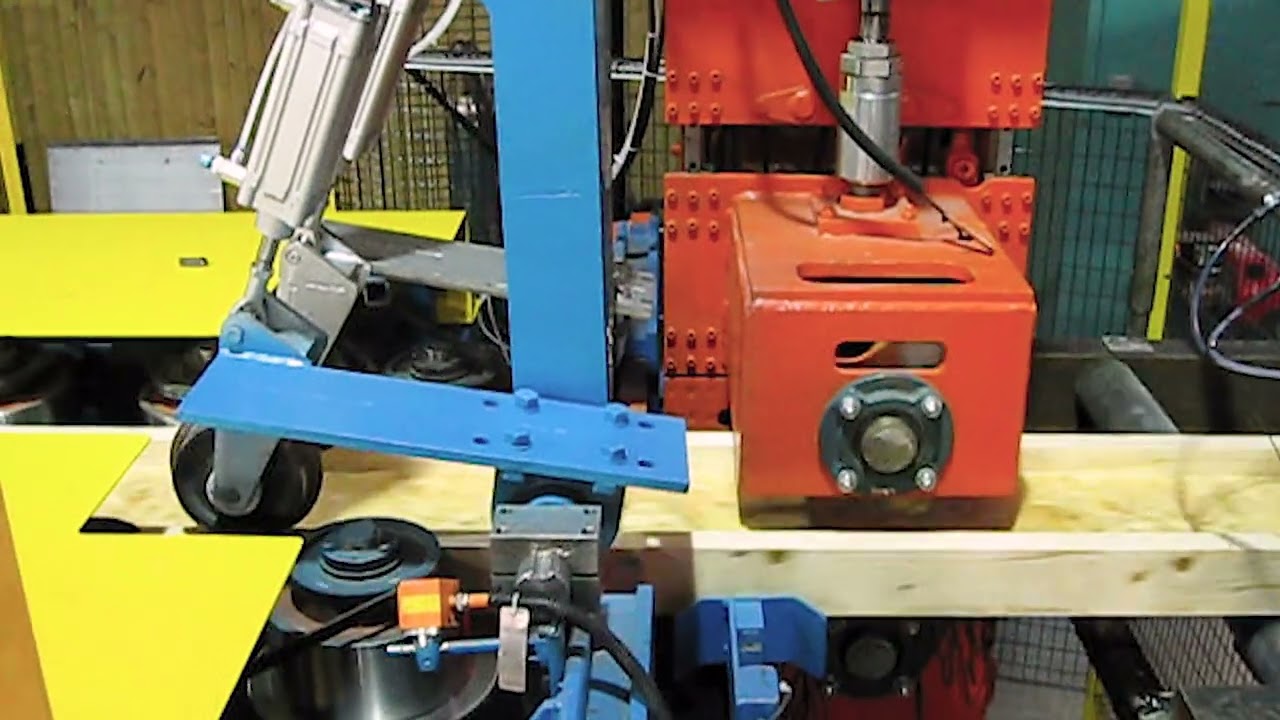

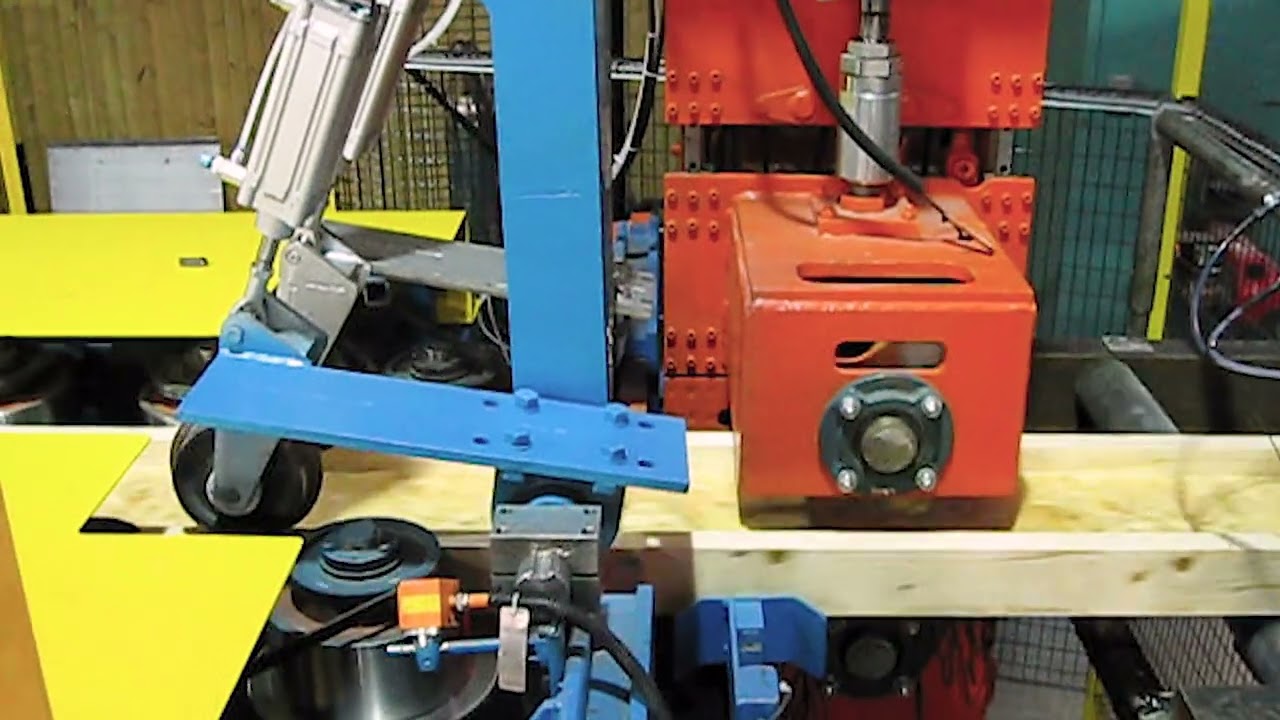

We take pride in engineering robust, durable equipment that stands the test of time — including building and testing the entire system in-house before sending it to you. This rigorous process is designed to maximize uptime and extend the life of your machinery, reducing maintenance costs and operational disruptions.

- Plywood

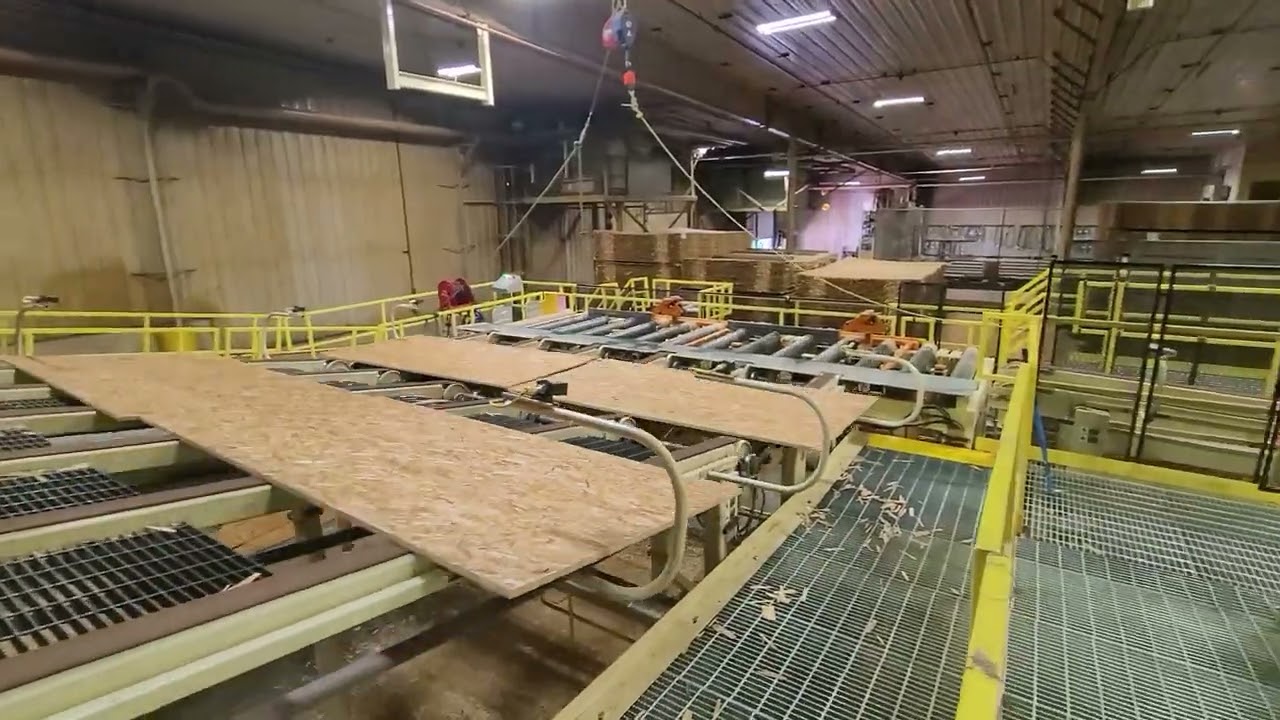

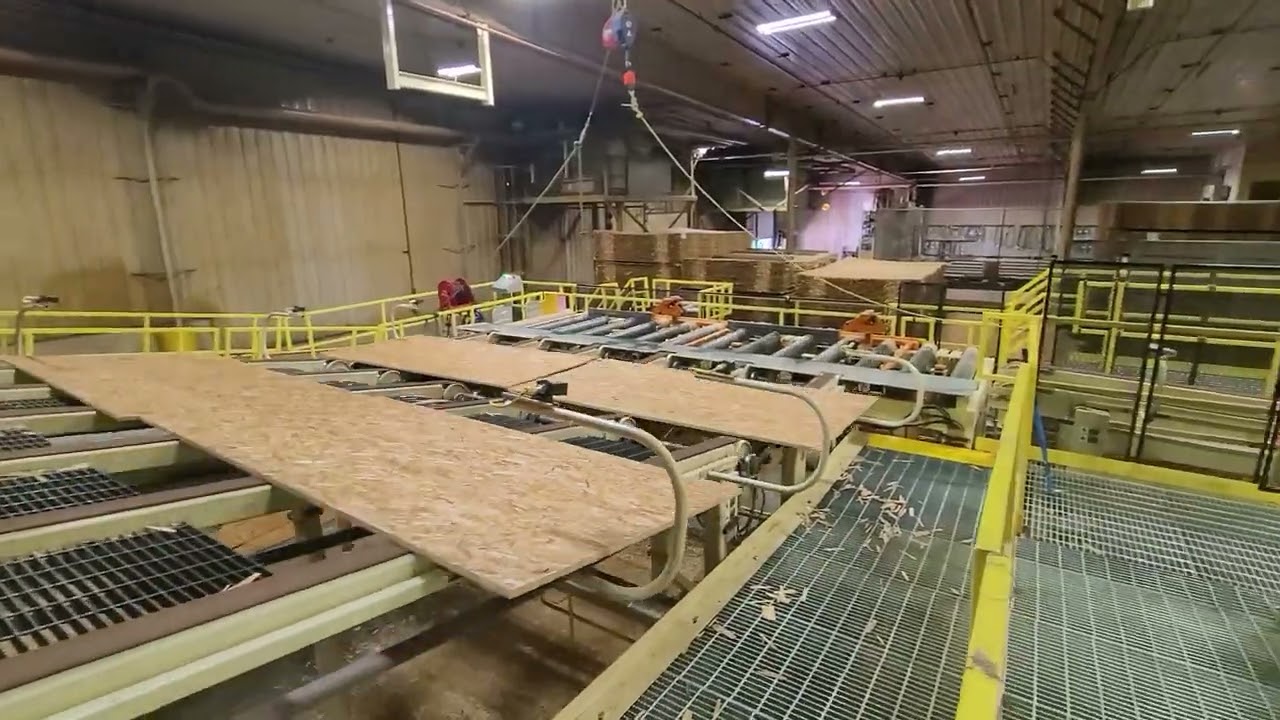

- OSB

- LVL

- I-Joists

- Siding & Trim

- More

Our tried-and-true equipment includes:

- Saw lines (grading, scanning)

- Sanding

- Panel repair

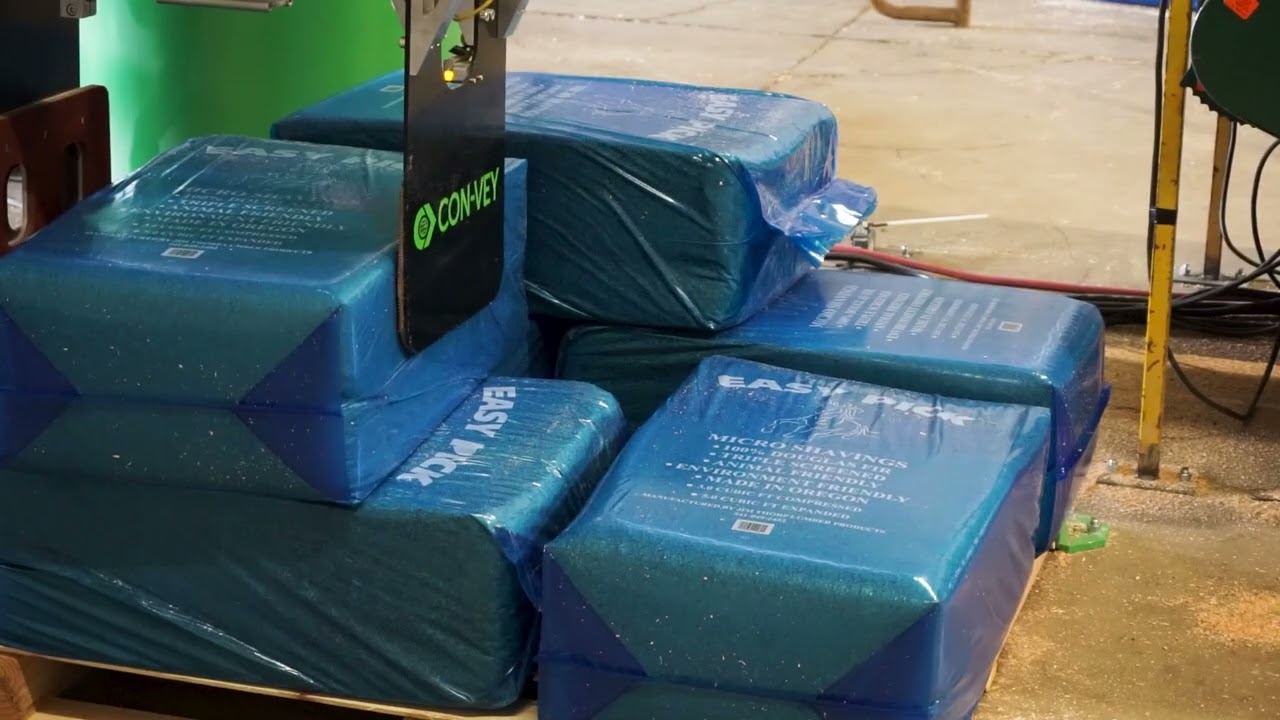

- Packaging

- Pre-prime & paint

- Siding

- Tongue & groove

- Oiler / sealant

- Laminating

Our tried-and-true equipment includes:

- Saw lines (grading, scanning)

- Sanding

- Rip lines

- Packaging

- Tongue & Groove

- Laminating

- Custom / Proprietary Products

Our tried-and-true equipment includes:

- Saw lines

- Rip lines

- Beam laminating

- Packaging

- Bundle Cutting (Precision End Trim)

- Sorting, Grading

- Marking, Stamping

Our tried-and-true equipment includes:

- Flange infeed & handling

- Web infeed, ripping, profiling

- I-Assembly

- Stacking

- Curing

- Nesting

- Packaging

- Remanufacturing

Our tried-and-true equipment includes:

- Rip lines

- Panel lines

- Lap lines

- Trim lines

- Moulding lines

- Paint lines

- Packaging

- Grading

- Curing & Ovens

- Specialty Panel Siding

We’re also well-versed in equipment for:

- Particle Board

- MDF (Medium Density Fiberboard)

- Foam and Insulation Panels

- Rubber Mats

- Ceiling Tile

- Gypsum and Drywall Panels

- Flooring

- Doors

- Lumber

- Decorative Panels

Plywood

Our tried-and-true equipment includes:

- Saw lines (grading, scanning)

- Sanding

- Panel repair

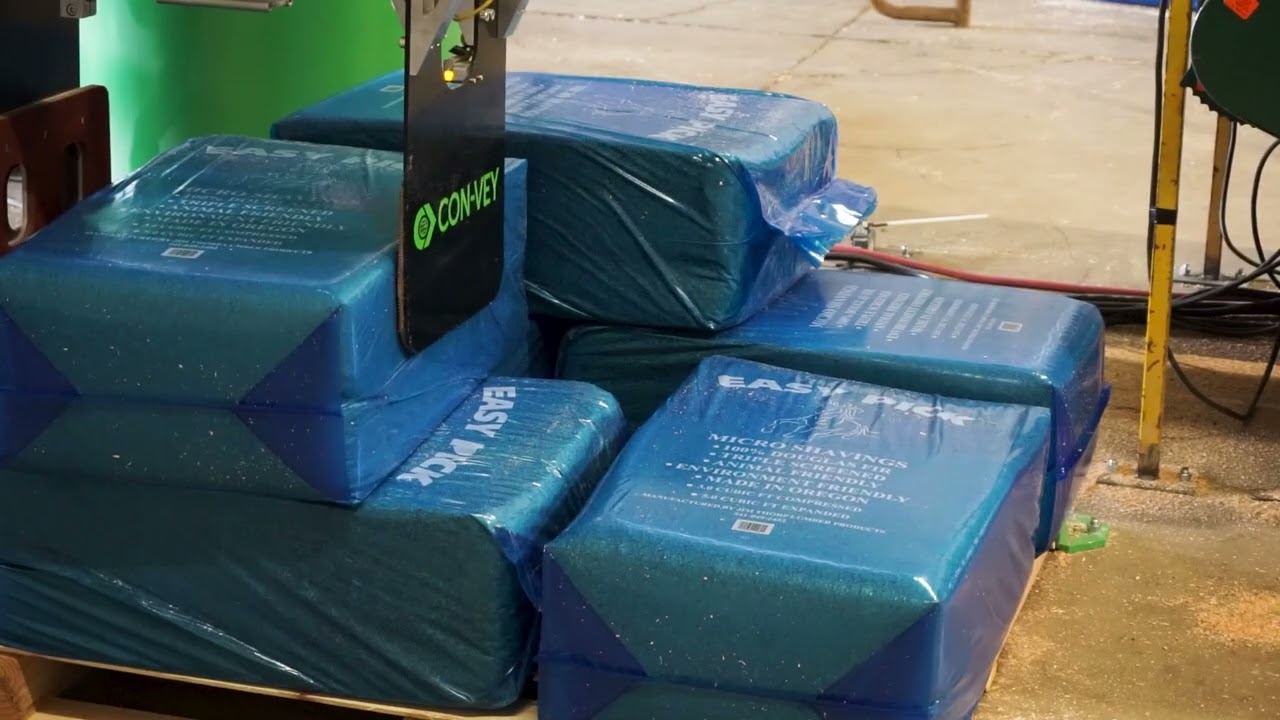

- Packaging

- Pre-prime & paint

- Siding

- Tongue & groove

- Oiler / sealant

- Laminating

OSB

Our tried-and-true equipment includes:

- Saw lines (grading, scanning)

- Sanding

- Rip lines

- Packaging

- Tongue & Groove

- Laminating

- Custom / Proprietary Products

LVL

Our tried-and-true equipment includes:

- Saw lines

- Rip lines

- Beam laminating

- Packaging

- Bundle Cutting (Precision End Trim)

- Sorting, Grading

- Marking, Stamping

I-Joists

Our tried-and-true equipment includes:

- Flange infeed & handling

- Web infeed, ripping, profiling

- I-Assembly

- Stacking

- Curing

- Nesting

- Packaging

- Remanufacturing

Siding & Trim

Our tried-and-true equipment includes:

- Rip lines

- Panel lines

- Lap lines

- Trim lines

- Moulding lines

- Paint lines

- Packaging

- Grading

- Curing & Ovens

- Specialty Panel Siding

More

We’re also well-versed in equipment for:

- Particle Board

- MDF (Medium Density Fiberboard)

- Foam and Insulation Panels

- Rubber Mats

- Ceiling Tile

- Gypsum and Drywall Panels

- Flooring

- Doors

- Lumber

- Decorative Panels

Don’t see something on this list?

Chances are it’s in our wheelhouse. Everything we do is custom, so start the conversation, and we’ll explore whether we’re a fit for your next project.

Fully Integrated Systems

Our custom automated machinery is designed to integrate seamlessly with your existing facility equipment, as well as with technologies from subcontractors. If we don’t build it, we’ll find someone who does — then work with them directly so you have one less thing to manage.

Con-Vey Controls

Our team has deep experience in designing, building, and programming control systems, including PLCs, MCPs, and HMIs. From custom enclosures and components to power distribution and on-site commissioning, we work with your team to bring right-fit technology to life in your facility.

Explore Con-Vey controls

Robotics Expertise

A leading force in automation, our robotics division is now an independent sister company: 7robotics. We work together closely to offer comprehensive robotics solutions to our clients.

Explore 7Robotics

Con-Vey Connect

Go beyond data collection with Con-Vey Connect, our proprietary analytics platform that works with any control system to provide advanced operational intelligence and maximize efficiency. Monitor plant performance 24/7, receive alerts for downtime reporting and predictive maintenance, track trends in real-time on the cloud, and even leverage augmented reality for troubleshooting and training.

Explore Con-Vey Connect

End-to-End Machine Support

Our partnership goes far beyond the equipment itself. Tap into Reliability+, our service program, for continuous support for your facility and operators. Or take advantage of our Parts & Service team to make the most of your existing equipment and keep production running.

How we support